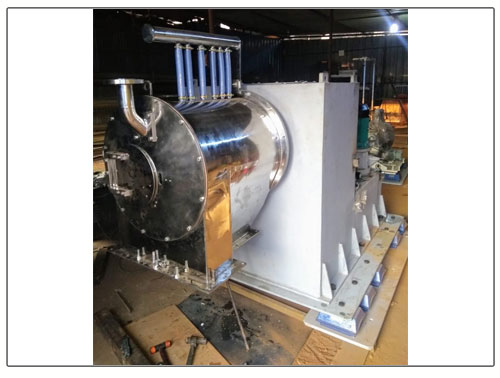

Shree sai Equipments & Services is a leading Pusher Centrifuge manufacturer in Pune, Maharashtra, India. We are also a top supplier of Pusher Centrifugein Pune, Maharashtra, India.

Our offered Centrifuge manufacturer in Pune are quality tested by our quality controller team on various parameters of quality in compliance as per industrial standards.

Solids collected on the screen and feed liquors drain through. The pusher plate rotates with the basket and reciprocates. On the forward stroke, the plate pushes solids along the screen, Consolidating the solids into a uniform cake. On the reverse stroke, fresh screen is exposed and more slurry is deposited. Cake dries as it moves along the length of the screen and wash liquor May be applied to remove impurities. Cake is pushed off the discharge end of the screen and directed to the Collection chute.

ABS, Ammonium Chloride, Ammonium Sulphate, borax, Common Salt, Cellulose acetate, Ferrous Sulphate, Dichlorobenzene, Hydroquinone, Hexamine, Nickel Sulphate, Lithium compound, Nitrocellulose, Potassium Carbonate, Potassium Chloride, Oxalic acid, Potassium Carbonate, Sodium Chloride, Sodium bicarbonate, Sodium Carbonate, Sodium Chlorate, Sodium Cyanide, Urea, and in general ANY Crystalline Inorganic salt.